Blog

Warehouse Safety and Fire Prevention Guidelines: Flue Spaces

Due to the high number of fire-related emergencies in warehouses, the National Fire Protection Association developed regulations that protect workers and facilities. Studies done by the organization indicate that there are about 1,410 warehouse fires every year. These fires result in an average of 20 injuries, two deaths and approximately $159.4 million in property damage every year.

Warehouses have a high fire load, making fire safety a big challenge. Additionally, installation and merchandise can spur on the spread of flames. Therefore, every warehouse must install a fire protection system to avoid becoming a part of the statistics. This article will look at some unique fire protection systems found in warehouses and focus on a lesser-known area of fire safety, flue spaces.

What Are Flue Spaces and Why Do They Matter?

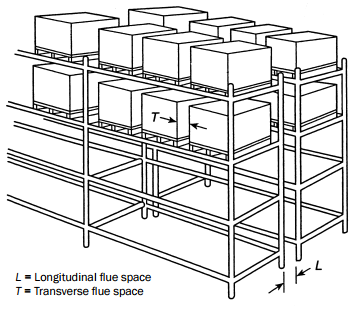

Flue spaces are found in rack storage areas in warehouses and are vertical lines of sight from the floor to the ceiling. The two common types of flue spaces are longitudinal and transverse flues.

- Longitudinal flues- These are the spaces between the rows of storage that are less than two feet wide and are perpendicular to the loading direction. Longitudinal flues greater than two feet wide are usually called aisles.

- Transverse flues- These are the spaces between storage in the loading direction.

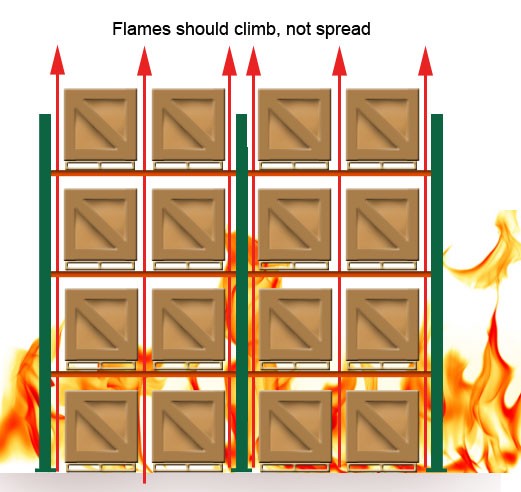

Flue spaces are vital because they allow heat from a fire to vent vertically. In their absence, ceiling level sprinklers won’t operate effectively or as quickly as they should. Proper spacing effectively slows down horizontal fire spread in the pallet racking system by letting the sprinklers disperse water in the vertical spaces between the racking and the stored product.

They also allow sprinkler water to get to the base of the fire through the racks to control the fire. Therefore, flue spacing is an essential requirement if you want your overhead sprinklers to work.

Requirements For Flue Spacing

The NFPA has clear guidelines on how flue spaces should be placed in warehouses. The guidelines state that:

- Between every load within a rack structure, there needs to be a 6-inch transverse flue space. To achieve such spacing, you can use rack spacers or snap-in dividers that can help maintain the required 6-inch spacing.

- A warehouse should also have a minimum longitudinal flue space of about 3 inches. This allows water from the overhead sprinkler system to penetrate the spacing effectively to control the fire. It also allows fire ventilation.

- If you store longer pallets in a rack, an alternative longitudinal spacing is necessary to account for the overhang.

Fire Protection Systems for Warehouses

In-Rack Sprinklers

A warehouse is the only place you will find overhead sprinkler systems and floor level sprinklers. Most people use both systems to get water flowing in the racks and apply it to the fire before it grows beyond management. If your warehouse deals in higher hazard commodities, you will benefit more from in-rack sprinklers.

Prewetting

Prewetting uses a sprinkler system to wet the fuel in the fire’s path, thus slowing down the fire from growing. While prewetting is an excellent concept on paper, it’s not very practical. This is because most warehouses contain encapsulated products that are impervious to prewetting. For example, items wrapped in plastics may not work with prewetting. As such, a warehouse needs to have a robust sprinkler system that will contain the fire if prewetting doesn’t work.

Early Suppression Fast Response

Early Suppression Fast Response is also a great way to prevent warehouse fires. The sprinklers work by getting to the fire immediately it begins. This means activating them earlier and discharging the water at a higher velocity than standard. The ESFR sprinklers only work if they reach the fire during its early stages. If blocked, they become ineffective.

Conclusion

Fire events in warehouses carry much risk and damage far more than any other work-related emergencies. As such, warehouses need to be well prepared for any fire-related issues that may occur. Before installing any racks in your warehouses, check with the local authorities to ensure your installation meets regulatory requirements in your state.