Custom Plastic Fabrication

Unifuse LLC‘s process creates containers with variable wall thickness providing the most crack and puncture resistant product available. Parts are manufactured using Vibrational Molding (VIM). Unifuse uses 100% virgin polyethylene (PE) FDA/USDA grade powders that form in and over aircraft quality aluminum molds under moderate heat. With virgin resins that have never been processed, VIM produces a product that has no stress lines and is virtually indestructible.

One of the great advantages of this process is that the tooling charges are just a fraction of injection, extrusion, thermoforming, blow or rotational molding. This makes it affordable to order parts in small quantities. Unifuse VIM has demonstrated success and effectiveness in the healthcare and pharmaceutical markets, as well as food service, material handling and OEM. Please contact us for further details and visit www.unifuse.com for additional information.

Features & Benefits

Made in the USA

100% Recyclable

Unique Shapes & Sizes

Low Tooling Costs

FDA/USDA Grade Resin

Resistant to corrosive materials

Temperature Resistant

Steam Cleanable

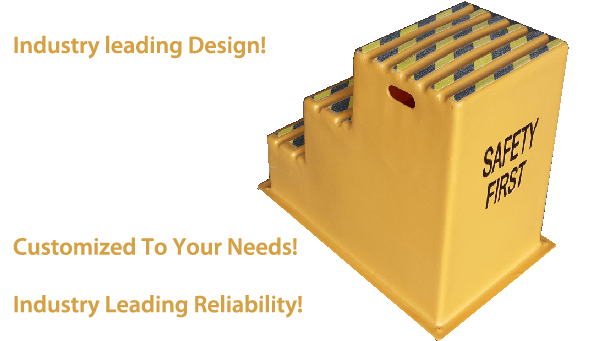

Safety First – Safety Three Step Custom Plastic Stool

Custom Plastic Health and Hospital Totes

Fabricated Plastic Tote Boxes