Blog

Shake It Off: Design of Seismic-Ready Pallet Racks

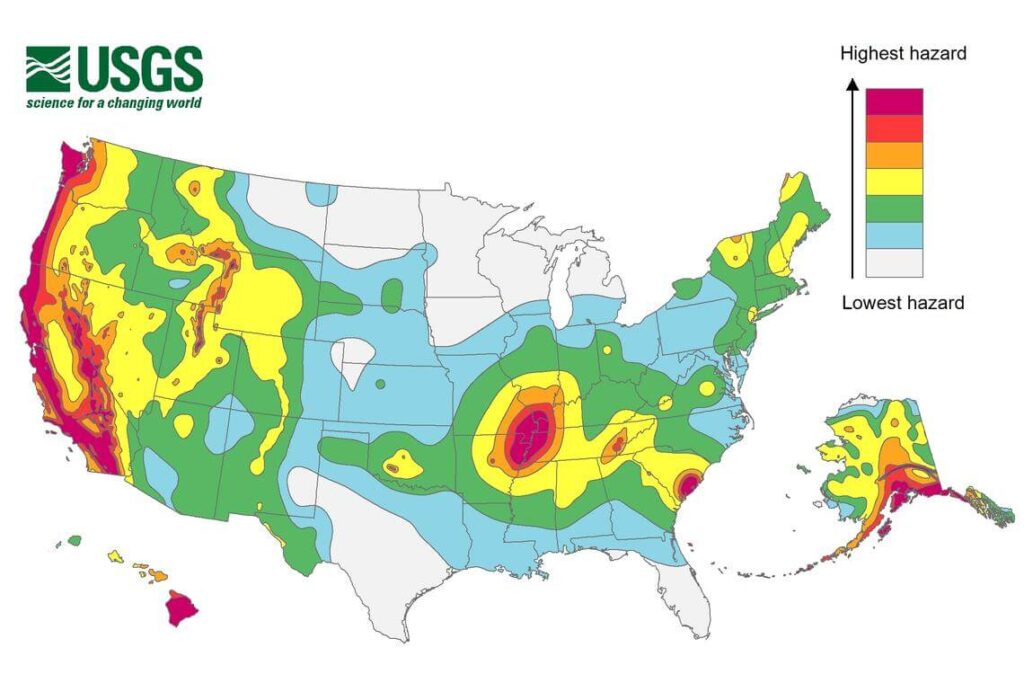

The seismic activity of an area is the type, frequency, and amplitude of earthquakes that are experienced over a given period. Even though only a few places in the U.S. are typically associated with major earthquakes, more than half of the U.S. falls within zones that see some level of seismic activity.

Consequently, if your warehouses fall within one of these areas, you should ensure that they have pallet racks designed to be seismic-resistant and make sure they are optimized for ultimate performance during any ground motion.

Effects of Earthquakes on your Warehouse

- Financial loss: when an earthquake occurs, it may lead to vandalization of your property and goods; this means losing finances.

- Material damage: earthquakes can cause damages to your warehouse structures, leading to a deficiency when serving your customers, and you will not be able to meet their demands.

- Human damage: this is the most significant damage that earthquakes cause. Humans work in your warehouses, and when it doesn’t have a good pallet rack design, the goods may fall on and harm your employees.

Pallet Rack Considerations to Ensure Readiness for Seismic Activity

You should use strong materials to make a pallet rack system to be considered earthquake ready. Half of the U.S. receives some seismic activities and depending on where your warehouse is located, you should employ a specific pallet rack design.

The RMI (Rack Manufacturing Institute) has a document titled “Specification for the Design, Testing, and Utilization of Industrial Steel Storage Rack,” which provides you with a complete listing and some fundamental calculations for engineers designing a pallet rack. These considerations include:

- Geographic location: Depending on the location of your facility in the U.S., it may have a higher or lower vulnerability to the impact of seismic activities on it. You should consider checking a map of seismic activities across the U. S. provided by RMI.

- Weight of Loads in the Racks: The force racks impact adjacent units such as the floor (down-aisle force) is critical when calculating the average weight of the loads on a rack. When this force is accurately calculated, it will help you set up a pallet rack.

- Daily Seismic Activities: There is an average of how much movement there is in the ground daily in every location. Having such an insight into how many seismic activities there are in a day will help you decide how much distance you should keep the racks apart.

- Materials and Construction: your pallet rack design and components should employ a strong steel gauge if your facility is in higher earthquake-prone areas. These components should include heavier bases to help support the rack on the floor.

The sizes for baseplates should be 5 x 5, 6 x 6, 4 x 8, 5 x 8, or 6 x 8 inches, and their thickness should be between 0.25 Inches – 0.375 inches. Also, consider making your system bolted since it will offer more durability and strength than welding the system.

While strong earthquakes may cause heavy damages to your facility, weak seismic activities would also cause significant damages that are not budgeted for. To avoid these damages, employ the above simple considerations before putting up your racks for pallets in your warehouse.

Have additional questions or ready to order pallet racking for your Pennsylvania, Delaware, or New Jersey warehouse? Reach out to the experts at Greystone Equipment Company.